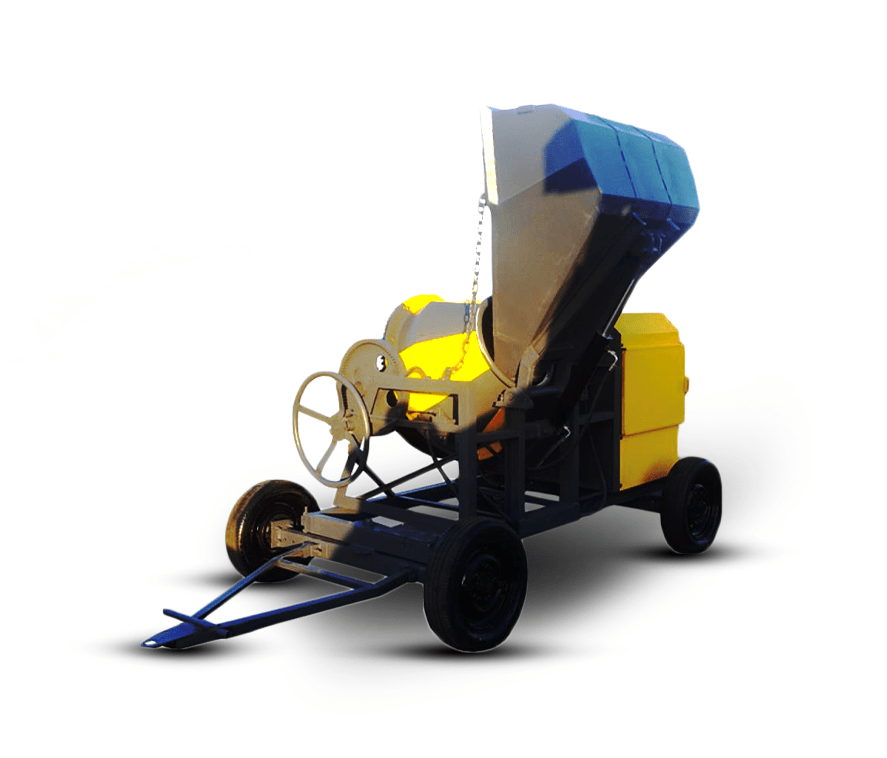

1 bag concrete mixer machine

We are the leading one bag concrete mixer machine manufacturer, supplier, trader, and dealer since 2009 in Guwahati. we sell different concrete mixers such as 1 bag concrete mixer machine, Concrete Mixer Machine With Lift, Laboratory Concrete Mixer Machine etc. at affordable price all over India. it can be shipped all over India.

Specification Of 1 bag concrete mixer machine

1 bag concrete mixer machine is a machine used for mixing concrete in construction work. The capacity of this concrete mixer machine is one bag. It has an air-cooled diesel engine that requires diesel as fuel. It is also Know as Concrete Mixer 10/7 CFT or 6 Hp Diesel Concrete Mixer.

The function of the 1 bag concrete mixer machine is to simply mix the concrete which can be used for construction purposes.

concrete mixer machine one bag have a base of ms still structure which is fitted with 14 inch numetic wheels.

Upon the frame ms mixing drum consisting with gears was fitted on the frame which both side has a bearing and to tilt the mixer drum a driver gear is also fitted in frame connecting to the mixing drum.

In the other side engine mounted to give the drive to the mixer. Engine output saft is connected with dooble grooved pully and it was connceted with belt to the mixing drum saft with a bigger wheel to reduce the RPM of the drum.

Engine rpm is 1500 and we reduce it to drum near about 30 rpm by which we can make a good mixing concrete.

concrete mixer machine one bag has a weight of maximum 700 kg because of it with the wheel to move this machine place to place is very easy.

it can be placed nearest to the construction site with the help of minimum labor.

Get 1 bag concrete mixer machine in Guwahati at the best price. fill the form if you want a quotation price from us. we don’t store or share your data with anyone we only use it to send you quotation

What Are the Advantages of One-Bag Concrete Mixer Machines?

The recent worldwide adoption of one-bag concrete mixer machines brings several significant advantages that promptly enhance the efficiency and quality of construction projects, thereby leading to proper utilization of time and building materials.

First, it saves a lot of time. Traditional concrete mixing methods involve heavy labor-intensive manual attention that eventually results in the unnecessary consumption of precious time. One-bag concrete mixer machines effectively streamline this long and stressed-out process, dramatically reducing the hours required to achieve a thoroughly mixed batch of top-quality concrete.

Uniformity in the concrete mixture is an additional factor for the structural integrity of any construction project. These machines ensure that the concrete batches provide the needed uniformity during the mixing process, thereby eliminating variations in strength and durability.

The ease of use in handling one-bag concrete mixer machines provides another advantage. Contemporary one-bag concrete mixer machines undergo industry-supervised designs that keep user-friendliness as a priority in mind. Intuitive controls and interfaces make them equally accessible and understandable to seasoned professionals and those new to the construction domain.

One factor builders generally approve of is the dramatic reduction in inflated labor costs. The automation provided by such machines significantly reduces the constant need for manual labor to pay utmost attention to the concrete mixing process. This benefit optimizes efficiency and minimizes the total strain construction projects feel compelled to deliver to the workforce.

The versatility of using one-bag concrete mixer machines presents an undying factor in supplementing their benefits too. Whether the project involves plain concrete, heavily reinforced concrete, or specialized, task-specific mixtures, these machines can cater to an unparalleled catalog of construction needs.

Related product

Specification Of Concrete Mixer Machine with Lift

Specification of Laboratory Concrete Mixer

It is a concrete mixer best use in laboratory.

The function of Laboratory concrete mixer is to make fine mixer of concrete.

Specification Of Pan Mixer Machine

Pan type color mixer is a mixer by which you can mix concrete with color. Which is basically used in colored concrete block making purpose.

Specification Of Reversible Concrete Mixer Machine

Reversible Pan mixer machine is a industrial machine used in big construction projects like Road making, Building making, Bridge making and etc.

The function of reversible concrete mixer machine is to finely mix the concrete. The machine has a drum type where one should input the raw concrete materials and then the when the machine is turned on the drum revolves around and the materials got mixed up and output the final mixer automatically when drum is moved reversely.

This machine is one of the mostly and widely used concrete mixer machine for a big construction project. It is best engineered concrete mixer machine so far build. It works very efficiently in almost every construction condition.

Specification Of Quater Bag Concrete Mixer

Specification Of Concrete Mixer with Hopper (one Bag)

This type of concrete mixer is actually comes along with a hydraulic hopper attached to it. Hopper facility reduce the loading time of raw material. It cause more production.

The function of concrete mixer is to mix the concrete for your required purpose.

Specification Of Color Mixer Machine (Drum Type)

Drum type color mixer basically used in dry color concrete mix. Which is used in concrete block which was made by hydraulic pressure technology. In a batch we can mix color with other raw material maximum total weight 100 Kg. Machine has a 2HP 3 Phase electric motor.

Visit Our offical site www.lotustraders.co.in

Specification of half bag concrete mixer

It saves time and money. If you’re looking for a quick fix to your concrete needs, then investing in a half bag concrete mixing machine is an excellent choice. These machines save you time by reducing the need to buy premixed concrete. They also save you money because you won’t have to pay for premixes.

2. It’s easy to use. With a half bag concrete mixer, you only need to add water and sand. No other ingredients are required.

3. It’s environmentally friendly. Because these machines use less energy than traditional methods, they help reduce carbon emissions.

4. It’s versatile. You can use them for both residential and commercial projects.

5. It’s durable. Unlike other concrete mixers, half bag concrete mixers are made with heavy duty materials. This means they will last longer and require fewer repairs.

Another advantage of using a half bag concrete mixer is that they are very easy to operate. All you need to do is add water and sand into the hopper and turn the handle. The machine will automatically start mixing the two together.

If you are looking for a high capacity concrete mixer, then you should consider buying one with a capacity of at least 1 cubic yard per hour. This means that you can easily make up to 100 cubic yards of concrete in an hour.

There are several reasons why you should invest in a half bag concrete mixer. First, it saves you time. This means that you will not spend as much time mixing concrete. Second, it saves you money. Because you will use less cement, you will save money. Third, it helps you avoid mistakes. With a half bag mixer, you do not have to worry about pouring too much water into the mixture. Fourth, it allows you to work more efficiently. Finally, it makes the process safer.

This machine is easy to operate. Just put the ingredients into the hopper and turn the handle. Then add water and start mixing. After that, just pour the mixture into the mold.

If you are looking for a good deal on a half bag concrete mixer, then you need to consider buying online. Online stores offer better prices than brick-and-mortar stores because they do not have overhead costs. We also provide free shipping options.

A concrete mixer with a diesel engine is a machine used for mixing concrete ingredients. The diesel engine provides power to rotate the drum, which ensures thorough and consistent mixing of concrete materials.

A 1 bag concrete mixer machine typically has a capacity of around 10/7 cubic feet, which means it can handle approximately one bag (50 kg) of cement per batch.

Kirloskar concrete mixer machines are known for their reliability, durability, and efficient performance. They are designed to withstand heavy-duty usage and deliver consistent mixing results.

Yes, small concrete mixer machines are ideal for DIY projects and small-scale construction tasks. Their compact size and portability make them convenient for use in various DIY applications.

Yes, concrete mixer machines are versatile and can be used for various applications, including repairs and patching. They ensure proper mixing of materials, resulting in a high-quality concrete mix for patching work.

Yes, portable concrete mixer machines are designed for easy transportation and can be used in remote or hard-to-reach areas. Their mobility allows them to be taken to construction sites with limited accessibility.

Regular cleaning, greasing moving parts, and inspecting for wear and tear are essential for maintaining a concrete mixer machine. Following the manufacturer’s maintenance guidelines is crucial for optimal performance and longevity.

The range for 1 bag concrete mixer machine price in India can vary based on factors such as brand, capacity, features, and location. For instance, a small concrete mixer machine from the brand “Lotus Traders” could be priced in the range of ₹80,000 to ₹150,000 or more. However, prices can fluctuate due to market conditions and other variables.

Safety is crucial when operating a concrete mixer machine. Operators should wear appropriate personal protective equipment, follow the machine’s operating instructions, and avoid placing hands or tools inside the mixer while it’s in operation.