Half bag concrete mixer

Get ready to enjoy the best Half bag concrete mixers on the market today. It’s easy to operate and requires no special skills or training.

Features and Specifications of half bag concrete mixer

A Half bag concrete mixer is an excellent device for making concrete mixers. Half bag concrete mixer makes it clean to provide big portions of concrete speedy and efficiently. It additionally permits you to govern the consistency of the combination via way of means of adjusting the velocity of the drum.

It saves time and money. If you’re looking for a quick fix to your concrete needs, then investing in a half bag concrete mixing machine is an excellent choice. These machines save you time by reducing the need to buy premixed concrete. They also save you money because you won’t have to pay for premixes.

2. It’s easy to use. With a half bag concrete mixer, you only need to add water and sand. No other ingredients are required.

3. It’s environmentally friendly. Because these machines use less energy than traditional methods, they help reduce carbon emissions.

4. It’s versatile. You can use them for both residential and commercial projects.

5. It’s durable. Unlike other concrete mixers, half bag concrete mixers are made with heavy duty materials. This means they will last longer and require fewer repairs.

Another advantage of using a half bag concrete mixer is that they are very easy to operate. All you need to do is add water and sand into the hopper and turn the handle. The machine will automatically start mixing the two together.

If you are looking for a high capacity concrete mixer, then you should consider buying one with a capacity of at least 1 cubic yard per hour. This means that you can easily make up to 100 cubic yards of concrete in an hour.

There are several reasons why you should invest in a half bag concrete mixer. First, it saves you time. This means that you will not spend as much time mixing concrete. Second, it saves you money. Because you will use less cement, you will save money. Third, it helps you avoid mistakes. With a half bag mixer, you do not have to worry about pouring too much water into the mixture. Fourth, it allows you to work more efficiently. Finally, it makes the process safer.

This machine is easy to operate. Just put the ingredients into the hopper and turn the handle. Then add water and start mixing. After that, just pour the mixture into the mold.

If you are looking for a good deal on a half bag concrete mixer, then you need to consider buying online. Online stores offer better prices than brick-and-mortar stores because We do not have overhead costs. We also provide free shipping options.

1 bag concrete mixer machine

Watch 1 bag concrete mixer machine Video

Specification Of 1 bag concrete mixer machine

1 bag concrete mixer machine is a machine used for mixing concrete in construction work. The capacity of this concrete mixer machine is one bag. It has an air-cooled diesel engine that requires diesel as fuel. It is also Know as Concrete Mixer 10/7 CFT or 6 Hp Diesel Concrete Mixer.

The function of the 1 bag concrete mixer machine is to simply mix the concrete which can be used for construction purposes.

1 bag concrete mixer machine have a base of ms still structure which is fitted with 14 inch numetic wheels.

Upon the frame ms mixing drum consisting with gears was fitted on the frame which both side has a bearing and to tilt the mixer drum a driver gear is also fitted in frame connecting to the mixing drum.

In the other side engine mounted to give the drive to the mixer. Engine output saft is connected with dooble grooved pully and it was connceted with belt to the mixing drum saft with a bigger wheel to reduce the RPM of the drum.

Engine rpm is 1500 and we reduce it to drum near about 30 rpm by which we can make a good mixing concrete.

1 bag concrete mixer machine has a weight of maximum 700 kg because of it with the wheel to move this machine place to place is very easy.

it can be placed nearest to the construction site with the help of minimum labor.

Get 1 bag concrete mixer machine in Guwahati at the best price. fill the form if you want a quotation price from us. we don’t store or share your data with anyone we only use it to send you quotation

Specification Of Concrete Mixer Machine with Lift

A Concrete Mixer is an essential part of the process of construction. It is commonly known as a cement mixer. It is an important component required for the construction of houses, roads, etc. It helps in mixing cement, sand, gravel, and water to form concrete. These mixers are often portable used in construction sites. These are very fast machines that save time, energy, and labor cost. Lotus mainly concentrates on manufacturing this concrete mixer which makes it workable with specific compressive strength.

This mixer is driven by DHPP‘N’ (diesel). It has a pulley on the top of the tower which engages buckets with the help of ropes. And further, with the help of fiction, motion is created in the wire rope. The power has modular angles to provide a certain height to what point the bucket can be lifted.

The hoist attached to it helps to lift up the cement mixture up to the required building floor for the construction of slabs, column filling, multi-stories, or any other construction-related activity.

It is a type of concrete mixer that has a lift or hoist attached to it. This concrete mixer used to mix cement mixture, sand, and other aggregates to produce concrete of the required grade. It is a machine with dual benefits. This single machine can do both the tasks of mixing cement and lifting or hoisting it with a single-engine. Our device is capable of preparing concrete mixture which gives ample amount of time to the workers to use the concrete before it hardens time.

Batch Capacity

Mixing Drum

Wheels

Lifting Capacity

Chassis

This type of concrete mixer is highly beneficial for low-cost apartments. Our brand uses high-quality raw material without harming nature. The qualities we use are tested by supervisors to ensure its process worthiness.

Watch Video

Specification of Laboratory Concrete Mixer

It is a concrete mixer best use in laboratory.

The function of Laboratory concrete mixer is to make fine mixer of concrete.

Specification Of Pan Mixer Machine

Pan type color mixer is a mixer by which you can mix concrete with color. Which is basically used in colored concrete block making purpose.

Specification Of Reversible Concrete Mixer Machine

Reversible Pan mixer machine is a industrial machine used in big construction projects like Road making, Building making, Bridge making and etc.

The function of reversible concrete mixer machine is to finely mix the concrete. The machine has a drum type where one should input the raw concrete materials and then the when the machine is turned on the drum revolves around and the materials got mixed up and output the final mixer automatically when drum is moved reversely.

This machine is one of the mostly and widely used concrete mixer machine for a big construction project. It is best engineered concrete mixer machine so far build. It works very efficiently in almost every construction condition.

Watch Video

Specification Of Quater Bag Concrete Mixer

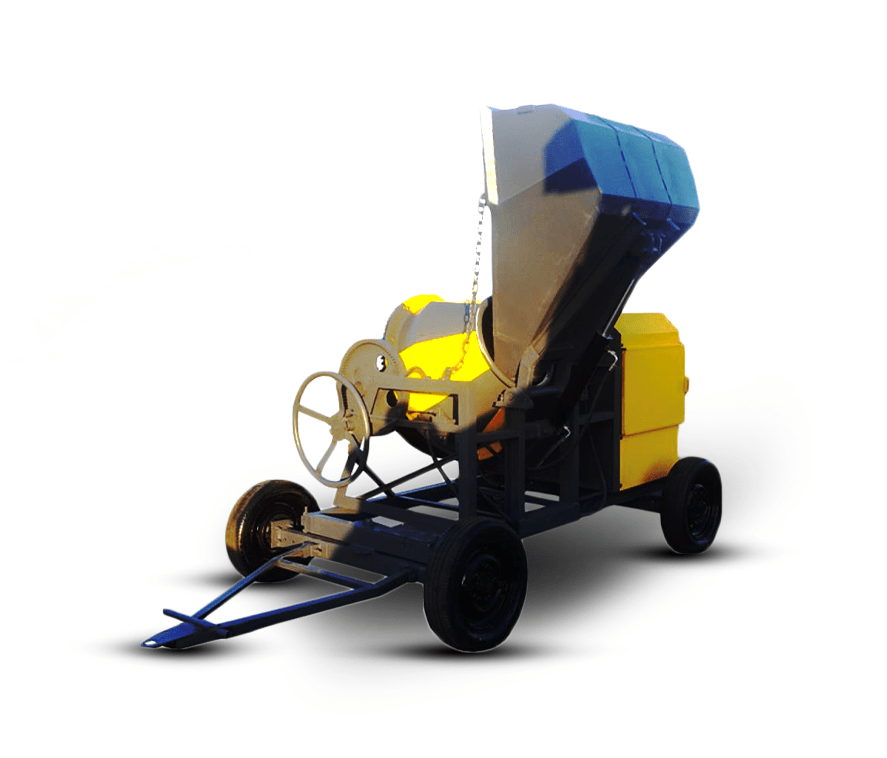

Specification Of Concrete Mixer with Hopper (one Bag)

This type of concrete mixer is actually comes along with a hydraulic hopper attached to it. Hopper facility reduce the loading time of raw material. It cause more production.

The function of concrete mixer is to mix the concrete for your required purpose.

Specification Of Color Mixer Machine (Drum Type)

Drum type color mixer basically used in dry color concrete mix. Which is used in concrete block which was made by hydraulic pressure technology. In a batch we can mix color with other raw material maximum total weight 100 Kg. Machine has a 2HP 3 Phase electric motor.