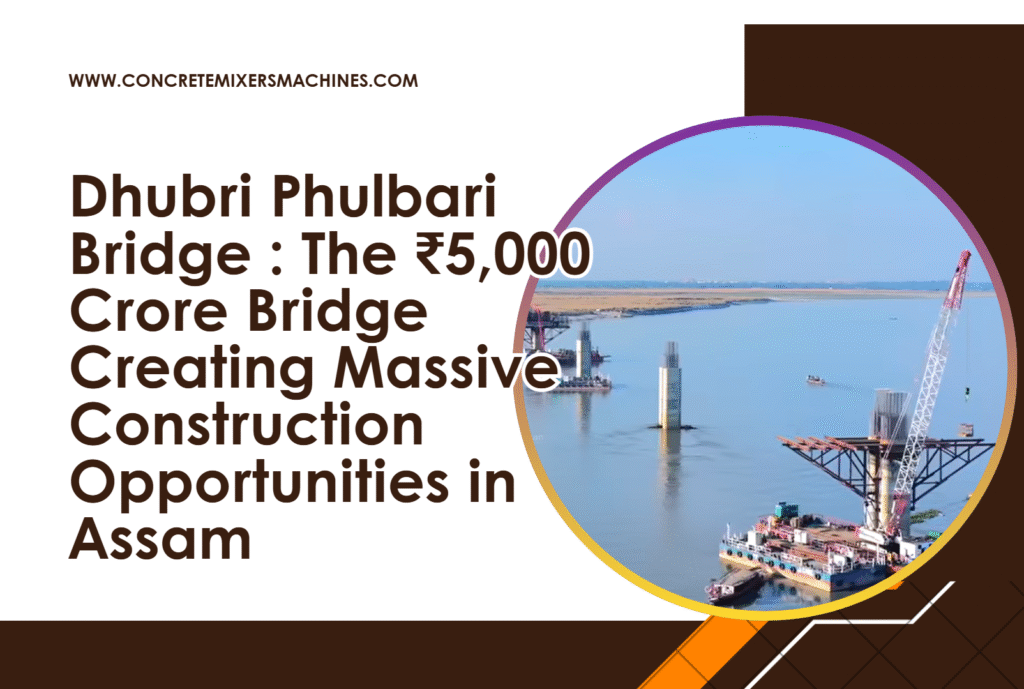

India’s infrastructure landscape is witnessing a historic transformation with the construction of the Dhubri Phulbari Bridge, set to become the country’s longest river bridge upon completion in 2028. Spanning an impressive 19.3 kilometers across the mighty Brahmaputra River, this four-lane engineering marvel is more than just a bridge—it represents a lifeline for economic development, regional integration, and enhanced connectivity across Northeast India.

For businesses involved in construction, infrastructure development, and equipment supply in Guwahati and surrounding regions, this project exemplifies the massive opportunities emerging from Northeast India’s infrastructure boom. As one of the most ambitious bridge projects in the country, the Dhubri Phulbari Bridge showcases the critical role that quality construction equipment and reliable materials play in executing large-scale infrastructure initiatives.

Understanding the Dhubri Phulbari Bridge Project

The Dhubri Phulbari Bridge is an under-construction four-lane extradosed cable-stay bridge that will connect Dhubri in Assam with Phulbari in Meghalaya along National Highway 127B. Positioned strategically close to the Bangladesh border, this bridge will fill a crucial missing link in the region’s transportation network, directly connecting western Meghalaya to Assam and providing the shortest route to the rest of India.

Key Project Specifications:

- Total Length: 19.3 kilometers (19,282 meters)

- Bridge Type: Four-lane extradosed cable-stay bridge

- Supporting Structure: 199 pillars

- Main Navigation Span: 12.625 kilometers

- Approach Viaducts: 3.5 km on Dhubri side, 2.2 km on Phulbari side

- Construction Company: Larsen & Toubro (L&T)

- Project Authority: National Highways and Infrastructure Development Corporation Limited (NHIDCL)

- Funding: Japan International Cooperation Agency (JICA)

- Total Project Cost: ₹4,997.04 crore (civil construction: ₹3,548 crore)

- Expected Completion: September 2028

The bridge is part of the North-East Road Network Connectivity Project Phase-03 and represents one of six proposed bridges across the Brahmaputra River, cementing its importance in the region’s connectivity infrastructure.

Current Construction Progress and Timeline

As of early 2025, construction work on the Dhubri Phulbari Bridge has achieved approximately 59 percent completion, with work progressing steadily on both the Assam and Meghalaya sides. According to Cabinet Minister and Phulbari legislator Abu Taher Mondal, about 35 pillars have been completed on the Assam side, while the Meghalaya side is experiencing minor delays but remains on track for the 2028 completion target.

Civil works commenced in 2019-2020, with L&T launching the bridge’s first precast segment in February 2022. The project involves sophisticated engineering techniques to address the challenges of building over the Brahmaputra, known for its high velocity and unstable flow patterns. Engineers are implementing earthquake-resistant design features, solar-powered lighting, and sustainable technologies to ensure the structure can withstand environmental pressures while meeting modern green infrastructure standards.

Transformative Impact: Cutting Travel Time from 5 Hours to 20 Minutes

The most immediate and tangible benefit of the Dhubri Phulbari Bridge will be the dramatic reduction in travel time and distance between Assam and Meghalaya. Currently, the journey between Dhubri and Phulbari spans approximately 205 kilometers and can take anywhere from five to seven hours, depending on whether travelers use ferries, which typically take 2.5 to 4 hours during monsoon season, or detour via the Naranarayan Setu.

Once operational, the bridge will:

- Reduce travel distance: From 205.3 km to just 19.3 km

- Cut travel time: From 5-7 hours to approximately 20-40 minutes

- Eliminate ferry dependency: Providing reliable year-round connectivity

- Create direct access: Connecting western Meghalaya, Barak Valley in Assam, and southern NE states (Manipur, Mizoram, Tripura) with the rest of India

This transformation will have cascading effects on trade, commerce, tourism, and daily commuting, fundamentally altering the economic landscape of the region.

Economic and Strategic Significance for Northeast India

The Dhubri Phulbari Bridge represents far more than physical connectivity—it’s a cornerstone for regional economic advancement and strategic integration. The project has been identified as having both strategic military significance and socio-economic importance, particularly for some of the most economically backward districts in Northeast India.

Key Economic Benefits:

- Enhanced Trade Corridors: The bridge will facilitate faster movement of goods between Assam and Meghalaya, opening new trade routes and reducing logistics costs. Commodities such as fertilizers, pulses, medicines, groceries, and finished goods that currently travel via boats will move more efficiently by road.

- Agricultural and Manufacturing Growth: Smoother transport will catalyze growth in agriculture, manufacturing, and service sectors, enabling local producers to access wider markets more quickly.

- Tourism Development: Improved connectivity will make tourist destinations in western Meghalaya, including Tura and the Garo Hills, more accessible, boosting the region’s tourism potential.

- Employment Generation: The construction phase alone has created thousands of direct and indirect jobs, while post-completion operations will generate long-term employment in transportation, logistics, hospitality, and related sectors.

- Western Exit Point: The bridge will serve as Meghalaya’s primary western entry and exit point, opening new economic opportunities and reducing the state’s dependence on northern border routes.

- International Trade Potential: Given its proximity to the Bangladesh border and connection to Kolkata ports, the bridge will enhance India’s Act East policy by strengthening trade links with Southeast Asia.

Infrastructure Development Opportunities in Northeast India

The Dhubri Phulbari Bridge is part of a larger infrastructure revolution sweeping across Northeast India. The region has witnessed unprecedented investment in roads, railways, airports, bridges, and power infrastructure, creating enormous opportunities for construction companies, equipment manufacturers, and material suppliers.

Major Infrastructure Initiatives in the Region:

- Special Accelerated Road Development Programme for North East (SARDP-NE)

- North East Special Infrastructure Development Scheme (NESIDS)

- Bharatmala Pariyojana for road infrastructure

- Multiple railway connectivity projects totaling 1,909 km

- Smart Cities Mission in Guwahati, Agartala, and Shillong

- Industrial hubs and Special Economic Zones (SEZs)

- Inland Water Transport (IWT) infrastructure development

For businesses in Guwahati and across Assam, these projects represent massive demand for construction equipment, raw materials, and specialized machinery. The region’s unique terrain—characterized by difficult hilly landscapes, riverine areas, and monsoon challenges—requires robust, reliable, and high-performance construction equipment.

The Role of Quality Construction Equipment in Major Infrastructure Projects

Large-scale infrastructure projects like the Dhubri Phulbari Bridge depend entirely on the availability of quality construction equipment and materials. The project’s success hinges on precision engineering, reliable machinery, and consistent material supply throughout the multi-year construction period.

Essential Construction Equipment for Bridge Projects:

- Concrete Mixer Machines: Bridge construction requires massive quantities of high-quality concrete for pillars, approach viaducts, and deck construction. Modern concrete mixer machines ensure consistent mixing ratios, proper material integration, and reliable output that meets stringent quality standards.

- Batching Plants: For projects of this magnitude, automated batching plants provide precise material proportioning and continuous concrete supply, essential for maintaining construction schedules.

- Tower Cranes and Mobile Cranes: Heavy lifting equipment is critical for positioning precast segments, steel reinforcements, and other structural components at significant heights.

- Piling Equipment: With 199 pillars supporting the bridge structure over the dynamic Brahmaputra River, advanced piling equipment ensures deep, stable foundations capable of withstanding high water velocity and seismic activity.

- Earth Moving Equipment: Approach roads and site preparation require excavators, bulldozers, and graders to handle large-scale earthwork operations.

- Transportation Equipment: Dump trucks and transit mixers transport materials across challenging terrain, ensuring timely delivery to construction sites.

Why Northeast Infrastructure Projects Need Local Manufacturing and Supply

As infrastructure development accelerates across Northeast India, the demand for locally manufactured and supplied construction equipment has never been higher. Projects face unique regional challenges that require specialized equipment solutions:

Regional Considerations:

- Terrain Challenges: Hilly and riverine landscapes demand compact yet powerful equipment

- Weather Conditions: Monsoon-resistant machinery with reliable performance in high humidity

- Logistics: Local supply chains reduce transportation costs and delivery times

- After-Sales Support: Proximity to manufacturing and service centers ensures quick maintenance and repairs

- Customization: Equipment adapted to region-specific construction requirements

Manufacturers and suppliers based in Guwahati and surrounding areas are strategically positioned to serve this growing market, offering advantages in logistics, local expertise, and responsive customer service.

Concrete Mixer Machines: The Backbone of Infrastructure Construction

Among all construction equipment, concrete mixer machines play a fundamental role in infrastructure development. For a project like the Dhubri Phulbari Bridge, which requires thousands of cubic meters of concrete for pillar construction, approach viaducts, and deck work, the reliability and efficiency of concrete mixing equipment directly impact project timelines and structural quality.

Modern Concrete Mixer Advantages:

- Consistent Quality: Automated mixing ensures uniform concrete quality across all construction phases

- Efficiency: High-capacity mixers reduce construction time and labor costs

- Versatility: Different mixer types accommodate various concrete grades and applications

- Durability: Robust construction withstands continuous operation in challenging environments

- Cost-Effectiveness: Efficient operation reduces material waste and operational expenses

For contractors and construction companies working on Northeast infrastructure projects, investing in quality concrete mixer machines from reliable manufacturers ensures project success, timely completion, and long-term cost savings.

Challenges and Engineering Innovations

Building a 19.3-kilometer bridge across the Brahmaputra River presents significant engineering challenges that require innovative solutions and cutting-edge construction techniques:

Primary Challenges:

- River Dynamics: The Brahmaputra’s high velocity, changing course, and flood patterns demand robust foundation design

- Seismic Activity: The region’s seismic vulnerability requires earthquake-resistant structural elements

- Terrain Complexity: Construction across water and challenging approaches on both banks

- Weather Constraints: Monsoon seasons limit working periods and impact construction schedules

- Logistics: Transporting heavy equipment and materials to remote locations

- Environmental Considerations: Minimizing ecological impact while maintaining construction progress

Engineering Solutions:

- Extradosed cable-stay design for enhanced structural stability

- Deep well foundations to anchor pillars securely in riverbed

- Precast segmental construction for faster, more efficient assembly

- Solar-powered lighting systems for sustainability

- Advanced monitoring systems to track structural health

- Use of high-grade concrete and steel for durability

Environmental and Social Impact

While the Dhubri Phulbari Bridge promises transformative economic benefits, it also presents challenges for traditional livelihoods and local communities. The improved connectivity will impact small boat traders who currently transport goods between Dhubri and Phulbari, potentially disrupting their traditional business models.

However, the project is expected to create far more opportunities than it displaces, including:

- New businesses along the bridge corridor

- Expanded markets for local agricultural products

- Tourism-related enterprises

- Logistics and warehousing facilities

- Service sector growth in hospitality and retail

The project’s development has included environmental impact assessments and resettlement plans to address community concerns and ensure inclusive growth.

The Future of Northeast Connectivity

Upon completion in 2028, the Dhubri Phulbari Bridge will stand as India’s longest river bridge and second-longest bridge over water (after Mumbai Trans Harbour Link), cementing Northeast India’s position as a critical component of the nation’s infrastructure network.

The bridge will serve as a catalyst for:

- Regional Integration: Strengthening connectivity among northeastern states

- Economic Corridors: Creating new trade routes and commercial opportunities

- Act East Policy: Supporting India’s strategic engagement with Southeast Asia

- Defense Logistics: Improving military mobility and strategic asset deployment

- Social Development: Enhancing access to healthcare, education, and government services

As the project nears completion, it will likely inspire similar mega-infrastructure initiatives across the region, further accelerating Northeast India’s economic transformation.

Opportunities for Construction Industry Stakeholders

The Dhubri Phulbari Bridge project exemplifies the enormous opportunities available for construction industry stakeholders in Northeast India:

For Equipment Manufacturers:

- Growing demand for specialized construction machinery

- Need for regionally adapted equipment solutions

- Long-term maintenance and service contracts

- Technology integration for modern construction methods

For Material Suppliers:

- Sustained demand for construction materials (cement, steel, aggregates)

- Premium pricing for quality-assured materials

- Long-term supply partnerships with major contractors

- Value-added services in logistics and delivery

For Contractors and Builders:

- Pipeline of mega-projects across the region

- Opportunities for specialization in bridge and highway construction

- Partnerships with national and international firms

- Capacity building and technology transfer

For Service Providers:

- Equipment rental and leasing opportunities

- Maintenance and repair services

- Logistics and transportation solutions

- Project management and consulting services

Conclusion: Building the Foundation for Northeast India’s Future

The Dhubri Phulbari Bridge represents more than an engineering achievement—it symbolizes Northeast India’s emergence as a dynamic region with immense growth potential. As construction progresses toward the 2028 completion target, the bridge is already reshaping expectations, investment patterns, and development trajectories across Assam, Meghalaya, and the broader Northeast region.

For businesses in Guwahati and across the region, particularly those in construction equipment manufacturing and supply, infrastructure development, and building materials, the message is clear: Northeast India’s infrastructure boom is creating unprecedented opportunities. Success in this market requires commitment to quality, understanding of regional needs, reliable after-sales support, and the ability to deliver equipment and materials that meet the demanding requirements of mega-projects like the Dhubri Phulbari Bridge.

As the longest river bridge in India takes shape over the Brahmaputra, it serves as a powerful reminder that great infrastructure projects require not just vision and funding, but also the reliable equipment, quality materials, and dedicated professionals who transform blueprints into reality. The Dhubri Phulbari Bridge is building more than a physical connection—it’s constructing a pathway to prosperity for millions across Northeast India.

Ready to be part of Northeast India’s infrastructure revolution? Whether you’re a contractor seeking reliable equipment, a project manager planning construction logistics, or a business looking to expand in the region, now is the time to position yourself in this rapidly growing market. The foundation for Northeast India’s future is being built today—ensure your business is equipped to participate in this historic transformation.